- Home

- Science

- Our Work

- Air Pollution

- Agriculture, Farming and Pesticides

- Asthma and other Lung Diseases

- Coronavirus Pandemic (COVID-19)

- Exposure to Chemicals and Dust

- Exposure to Nanomaterials

- Human Exposure

- Neurodegenerative Diseases

- Musculoskeletal Disorders

- Occupational Cancer

- Sustainable Working

- Sustainability and Climate Change

- Stress, Wellbeing and Psychosocial Issues

- COVID-19 IOM Study of Face Coverings in Retail Environments

- Styrene Study

- PROTECT COVID-19 National Core Study

- Firefighters and Cancer – IOM Report

- MORtality Study of Former Professional Footballers in England and Wales (MORSE) Study

- Our Scientists

- Our Expertise

- Nano Material Services

- Development and Management of Data and Information Systems and Services

- Ergonomics Design and Evaluation

- Epidemiological Studies & Methods

- Exposure Assessment

- Health Impact Assessment (HIA) and Risk Assessment

- Policy Evaluations

- Study Design and Statistical Analysis

- Systematic Reviews and Meta-analyses

- Toxicology

- Workplace Cluster of Disease

- IOMLIFET

- IOM Scientists Advocate Tighter Standards for Airborne Dust at Work

- Research Project on Work Related Musculoskeletal Disorders

- Styrene Study

- Firefighters and Cancer – IOM Report

- IOM Library

- Contact our Research Experts

- Our Work

- Occupational Hygiene

- Case Studies

- Air Quality Sensors

- COSHH Assessment

- Dust Exposure

- Environmental Management

- Face Fit Testing

- Hand-Arm Vibration

- Indoor Air Monitoring

- Laboratory Animal Allergens

- Legionella Risk Assessment

- Local Exhaust Ventilation

- Noise Monitoring

- Thermal Exposure Monitoring

- Workplace Exposure Limits (WELs)

- Welding Fumes

- Remote Monitoring Services

- Formaldehyde Exposure Monitoring

- Biological Agent Exposure Monitoring in Waste Management

- Chromium VI

- Occupational Hygiene – Quick Quote

- Lab Services

- Asbestos and other Fibres

- Asbestos Sample Testing

- Asbestos Proficiency Testing

- Dust and Crystalline Silica

- Lead in Paint

- Metals, acid anions, acid gases

- Microbiology

- Pharmaceuticals

- Solvents & Other Organic Chemicals

- Hazard Assessment and Toxicology

- Dustiness Testing of Bulk Powders

- Lab Services Quick Quote

- Training

- Courses

- Face Fit Tester Training – Combined 2-day Course

- Face Fit Tester Training – Day 1 Qualitative Test Method

- Face Fit Tester Training – Day 2 Quantitative Test Method

- One Day Ventilation Maintenance Course

- BOHS Five Day Authorised Person (Ventilation) Course

- BOHS Three Day Competent Person (Ventilation) Course

- BOHS Two Day Competent Person (Ventilation) Refresher Course

- Contact our Training Team

- Courses

- Hospital Ventilation

- Authorising Engineer

- Dentistry Post Lockdown

- Design Review

- Independent Review

- Diathermic pen and Electro surgical tool testing

- Microbiological Monitoring

- Systems Refurbishment and Upgrade

- Validation and Verification Testing

- HSE COVID-19 Spot Check Inspections

- Training

- Contact Our Hospital Ventilation Experts

- Consultancy

- Our Company

- Contact Us

- Menu Item

Dustiness Testing of Bulk Powders to EN 15051-2:2013+A1:2016

Important in material characterisation, dustiness evaluation is needed for all bulk powders under REACH.

At the IOM, we help you to stay compliant with regulation whilst mitigating the risks to people and processes associated with bulk powders. Our dustiness testing services are conducted using the rotating drum method, provide valuable insights to help you handle materials safely.

Identifying and Minimising Exposure Risks

Dustiness testing allows us to assess the propensity of materials to generate airborne dust during handling. By accurately measuring inhalable, thoracic, and respirable dustiness mass fractions, we can help you identify and understand the potential exposure risks faced by your workers. This knowledge allows you to put in place effective control measures to safeguard their health and well-being.

Ensuring Compliance with REACH

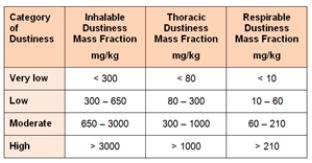

All handling of bulk powders require compliance with REACH. Our dustiness testing services gives you all the information you need to stay compliant. Materials are classified as outlined in the European standard, as detailed below:

Process improvement and protecting worker health

A thorough understanding allows you to optimise ventilation and filtration systems, reduce material loss, and prevent contamination of machinery and products. Meaning staff are being kept safe from occupational disease and processes are more efficient and cost-effective.

Other material characterisation testing

Our dustiness testing is just one aspect of our comprehensive material characterisation services. We go beyond dustiness evaluation to provide you with a better understanding of your materials. By analysing particle size distribution, moisture content, and bulk density, we offer valuable insights that inform risk assessments and give context to control measures that may be in place.

Our additional specialised characterisations, including SWFF analysis, nanoparticle characterisation, and morphology & chemical analysis, further enhance your understanding of potential exposure to dust, elemental composition, and bio-durability, enabling you to make well-informed decisions to protect both your workers and your operations.

Take proactive steps to evaluate and mitigate dust-related risks in your bulk powder handling processes. Contact us today.